1. Introduction

In today's world, there has been a notable increase in the utilization of internal combustion engine-powered cars, resulting in a significant escalation in the consumption of gasoline and diesel fuel. Furthermore, the issue of environmental pollution arises from the excessive release of hazardous pollutants as a consequence of incomplete combustion of fuel in internal combustion engines. This process generates several by-products, including but not limited to NOx, CO, SO2, CmHn, and others. Consequently, numerous research endeavors have been undertaken with the objective of substituting or progressively diminishing the utilization of fossil fuels, such as gasoline and diesel, in internal combustion engines. Hydrogen fuel is deemed a viable solution due to its capacity to undergo combustion and subsequently transform the resulting heat and pressure into mechanical energy, similar to the operational principles of internal combustion engines fueled by fossil fuels. Nevertheless, it is worth noting that hydrogen possesses a significantly greater energy density in comparison to conventional gasoline. Specifically, one kilogram of hydrogen has the potential to release three times more heat than an equivalent mass of gasoline. Moreover, hydrogen combustion is entirely environmentally friendly, as the sole byproduct generated is water.

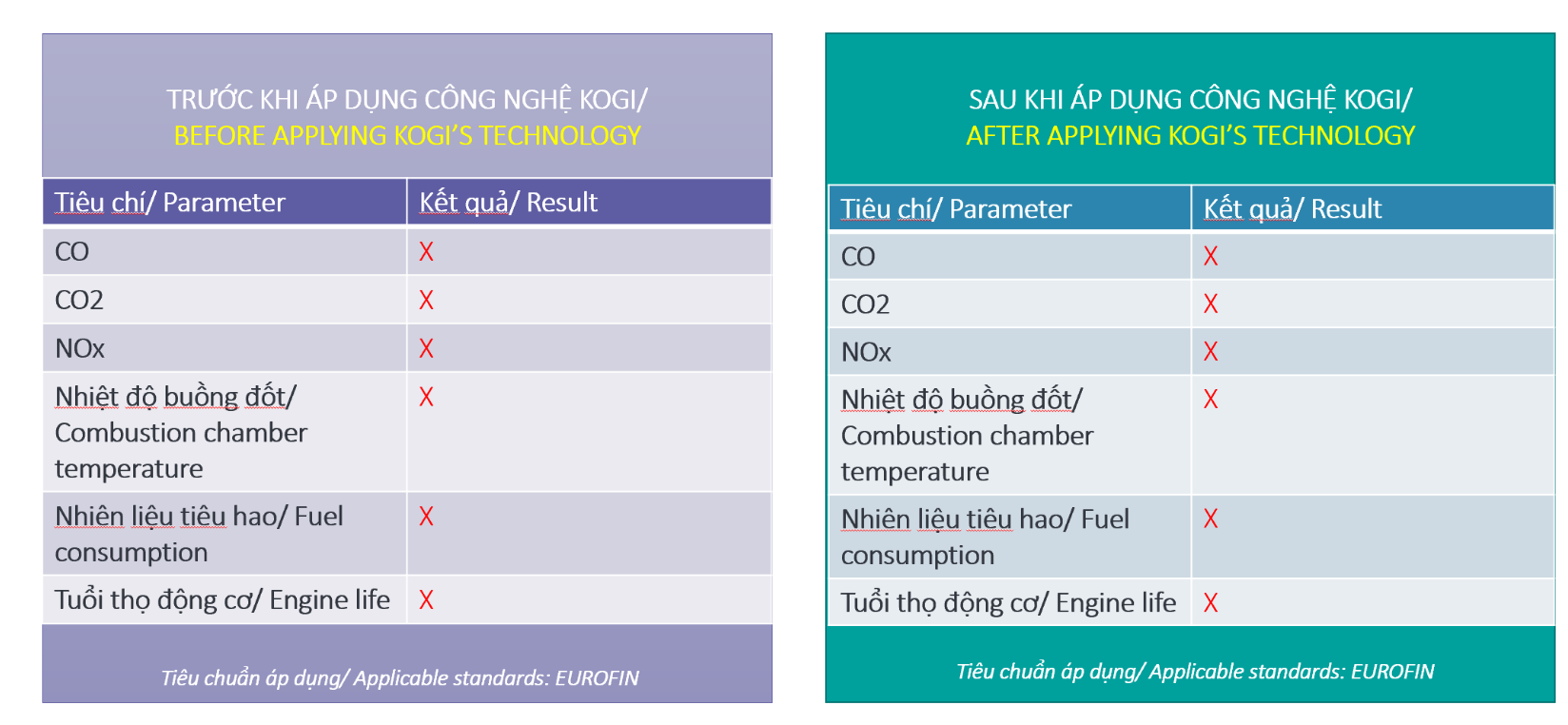

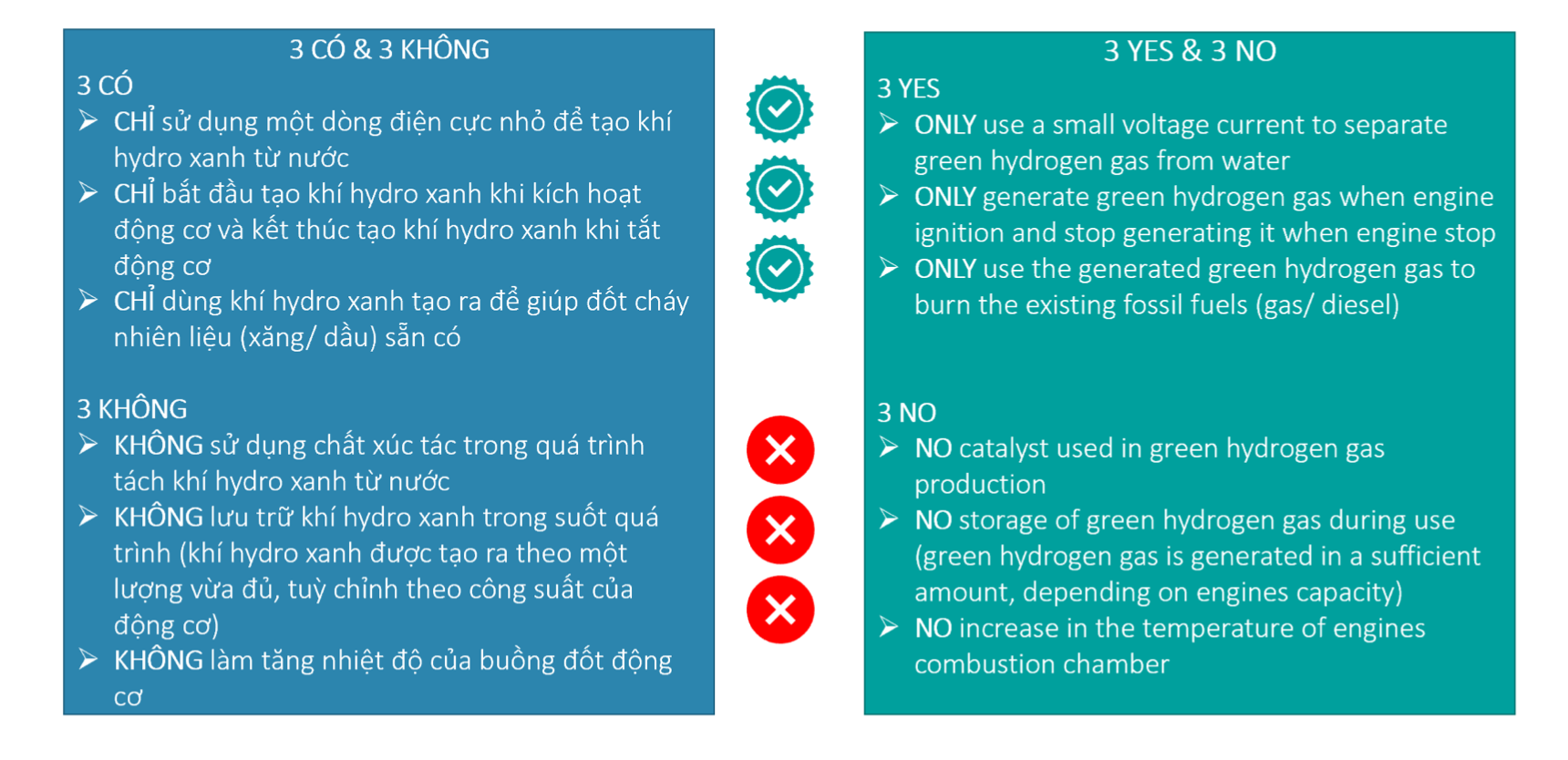

Water electrolysis, a process that involves the utilization of electric current to separate water molecules, offers a direct means of harnessing hydrogen gas as a fuel source, obviating the need for external hydrogen refueling. Presently, numerous studies have emerged worldwide about water electrolysis systems aimed at supplying hydrogen fuel for internal combustion engines. However, it is well acknowledged that these systems exhibit limited efficacy. The aforementioned publications have not developed a system that exhibits a great degree of flexibility, since they continue to rely on traditional water sources for the process of electrolysis. Furthermore, the utilization of catalysts remains necessary in these systems, and a comprehensive and self-contained electrical system has not been devised as of yet. Hence, the technical infrastructure of KOGI Group has been developed with the aim of addressing the aforementioned constraints.

2. About KOGI Group’s technology

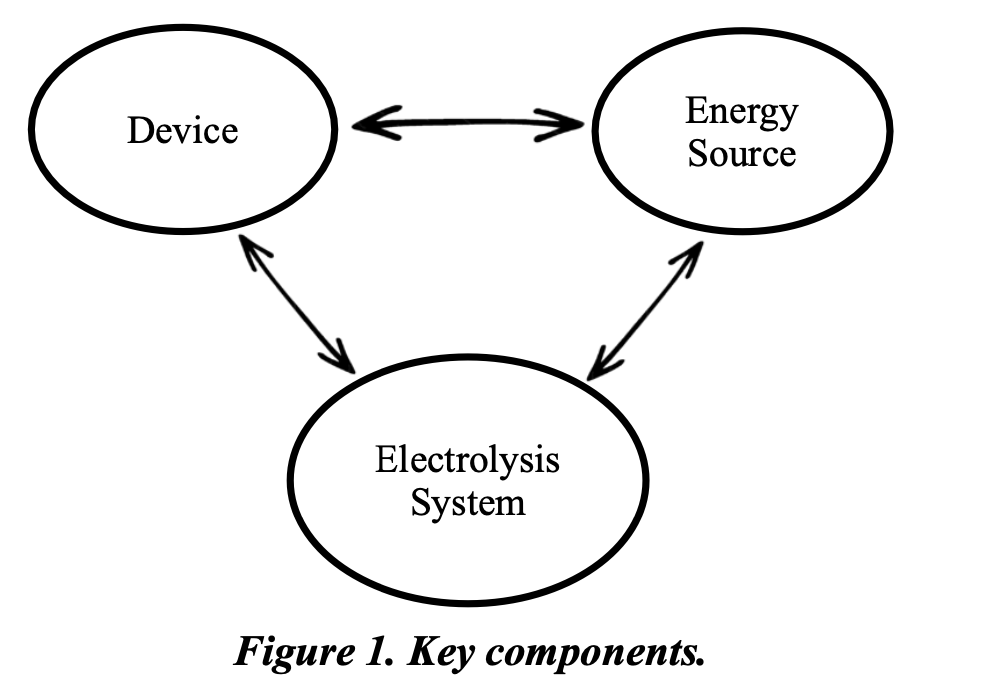

This technology involves the utilization of hydrogen fuel combined with traditional fuels, such as gasoline and diesel, to facilitate the functioning of vehicle engines, depending on the specific engine type. The objective is to minimize fuel consumption and eradicate emissions within the combustion chamber prior to their release into the external environment. The hydrogen fuel source is generated and utilized in situ through the process of water electrolysis during vehicle operation. The technological model, in essence, comprises three primary components that exhibit a strong interconnection (Figure 1). The primary purpose of the energy source is to provide power to the electrolysis system, which facilitates the production of products that are subsequently utilized by the equipment. The various constituents within this model are effectively administered and engage in mutual communication by means of a central controlling entity.

2.1 Operating mechanism

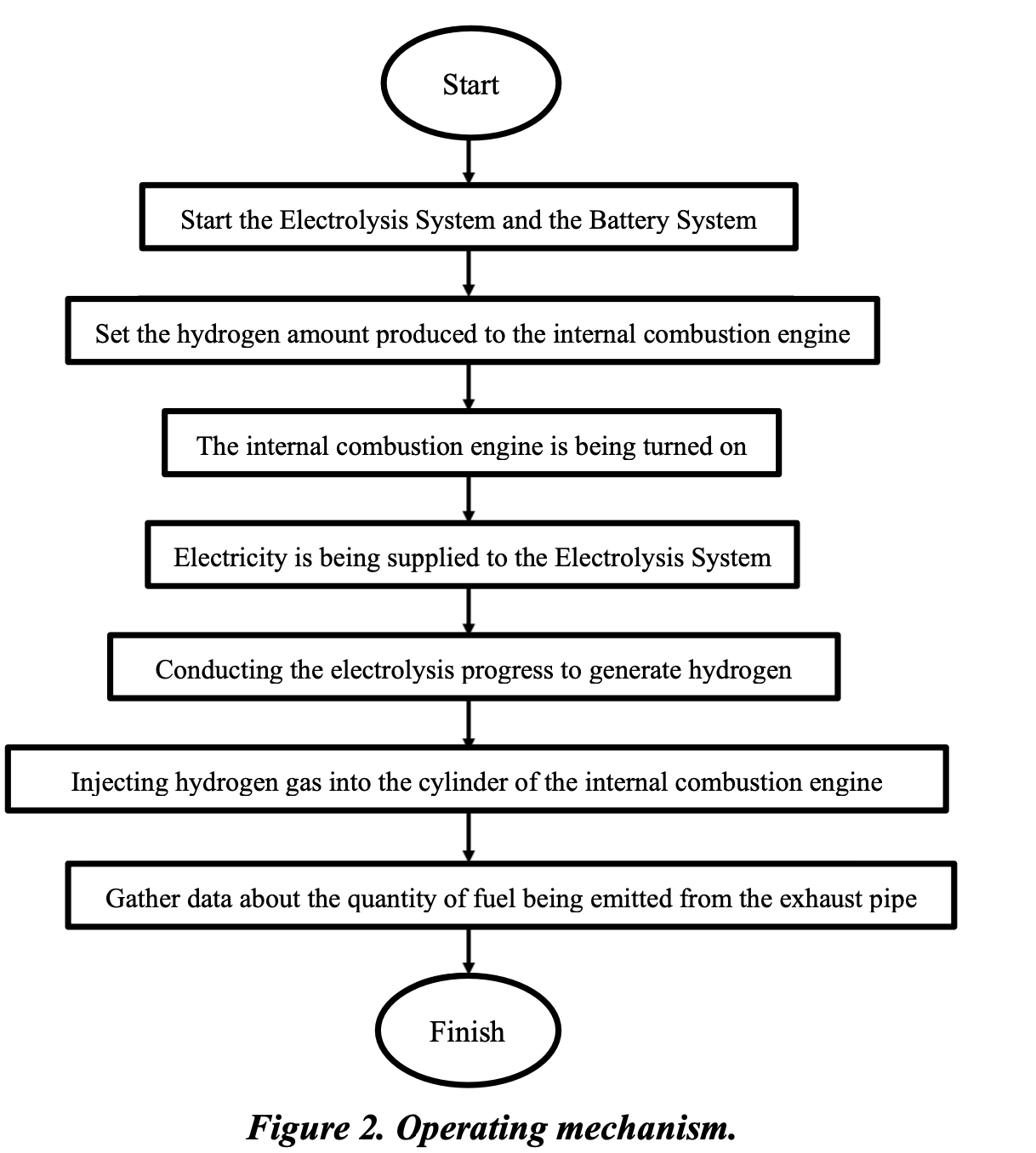

The operating mechanism of the technology systems is described as follows:

-

First, the electrolysis system and batteries are integrated into the existing vehicle system 2. The operator has the ability to determine the quantity of hydrogen that will be delivered to the engine by utilizing the control screen. Subsequently, the controller will do calculations based on the predetermined parameters and determine the optimal quantity of hydrogen to be introduced into the combustion chamber of the engine.

-

Upon initiating the vehicle, the controller will draw electrical power from the car's electrical system to activate the ignition engine. Simultaneously, a combination of fuel (either gasoline or diesel) and air will be introduced into the combustion chamber. The topic of interest is engine combustion. The mentioned blend will undergo combustion within the internal combustion engine in order to generate mechanical energy.

-

Once the engine has been activated, the controller will persistently utilize the electrical system and/or battery system of the vehicle to supply energy for the functioning of the electrolysis system. In order to facilitate the water electrolysis process, it is necessary to convert the existing direct current, which is currently being used in the electrolysis system, into alternating current with amplified amplitude and frequency. The present conversion process is executed by the initial inverter circuit. As a result of this procedure, the device has the capability to electrolyze various water sources, including tap water, distilled water, deionized water, and others. The electrolysis device utilizes an electric current within the range of 1 to 20 amperes. The process of electrolysis occurs when an electric current passes through the metal electrode, resulting in the decomposition of water molecules into hydrogen gas. The hydrogen gas that is produced will undergo purification and cooling processes by being directed through a water tank known as a hydrogen filter.

-

Subsequently, the cleaned hydrogen gas will be directed towards the combustion chamber, also known as the cylinder, of the engine. Based on the original configuration and computational analysis, an appropriate quantity of hydrogen will be introduced into the cylinder. The process involves the combination of hydrogen gas with air and fuel, such as gasoline or diesel. Additionally, this amalgamation will undergo combustion and execute the operational procedures similar to traditional fuel sources.

-

In order to optimize energy efficiency and mitigate the release of harmful byproducts, a post-combustion exhaust sensor will be employed to gather data from the exhaust pipe. Subsequently, the controller will analyze this data and provide notifications to the operator, pushing them to make necessary adjustments to the fuel load.

2.2. Detail of the main system

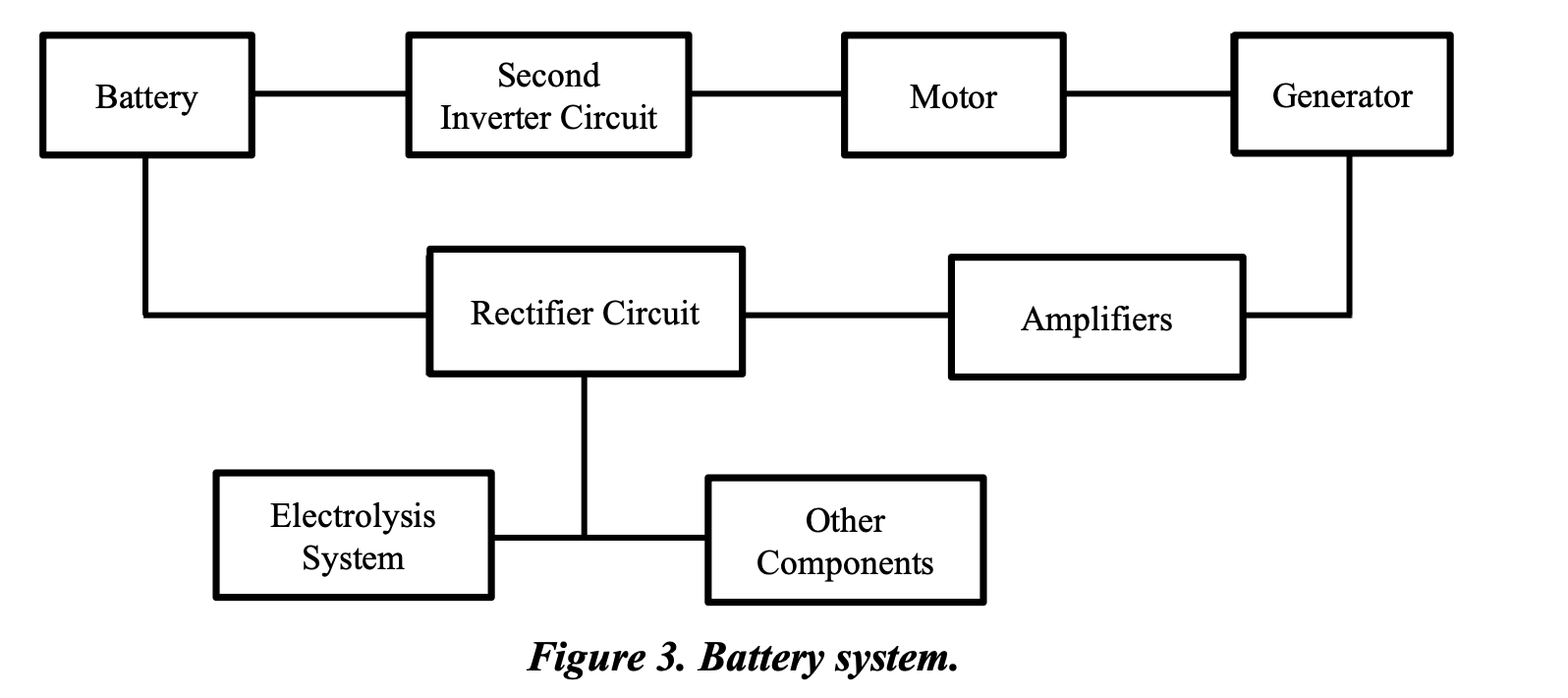

2.2.1. Battery system

The battery power supply for the battery system is comprised of two or more interconnected batteries. During the operation of the battery system, the flow of electric current will be directed through the second inverter circuit. The process involves the conversion of direct current into alternating current through the amplification of both amplitude and frequency of the current. The alternating current subsequently induces rotation in the motor, resulting in the generation of an electromagnetic field. When subjected to an electric field, the generator will generate an alternating current characterized by a consistent fluctuating voltage. The amplifier circuit serves to increase the voltage and power of this particular current. The amplified current is thereafter transmitted through the rectifier circuit, ultimately transformed into direct current for the purpose of powering the electrolyzer and other components of the vehicle. Simultaneously, a portion of the existing electric current will flow back to replenish the initial battery's charge.

2.2.2. Water electrolysis system

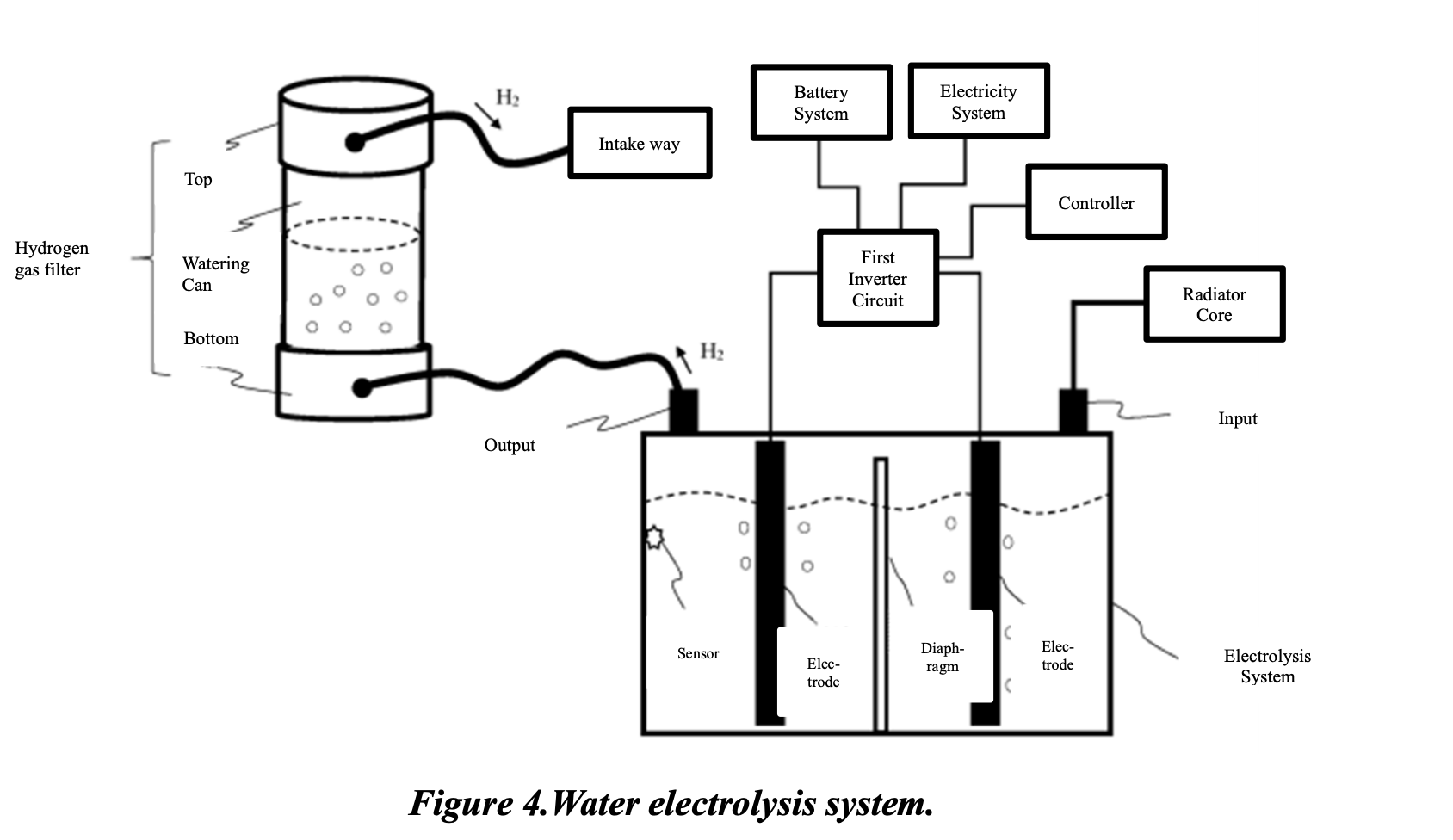

Figure 4 illustrates the electrolysis system, comprising a water electrolysis apparatus and a hydrogen gas filtration system. Its primary function is to facilitate the process of water splitting, hence producing hydrogen gas for the purpose of supplying the engine. The system's operational framework encompasses the subsequent stages:

-

The electrolysis equipment will be operated using the electrical system or battery system of the vehicle. The electrical current that is being supplied to the system will need to pass through the initial inverter circuit. In this context, the conversion of direct current into alternating current of appropriate amplitude and frequency is necessary to facilitate the process of water electrolysis.

-

When the electric current passes through the electrode (with a magnitude of 1 A to 20 A) in a water environment, the process of splitting water molecules into hydrogen gas will occur.

-

The hydrogen gas produced is directed to the hydrogen gas filter. This device has the role of cleaning hydrogen gas and reducing the temperature of the generated hydrogen gas stream.

-

During operation, water in the electrolysis tank is consumed to split into hydrogen, so the amount of water in the tank will be lost over time. When the water level drops below a specific (predetermined) level, the sensor sends a signal to the controller to perform the refilling process. Once the water level reaches the required level, the refilling process will be turned off.

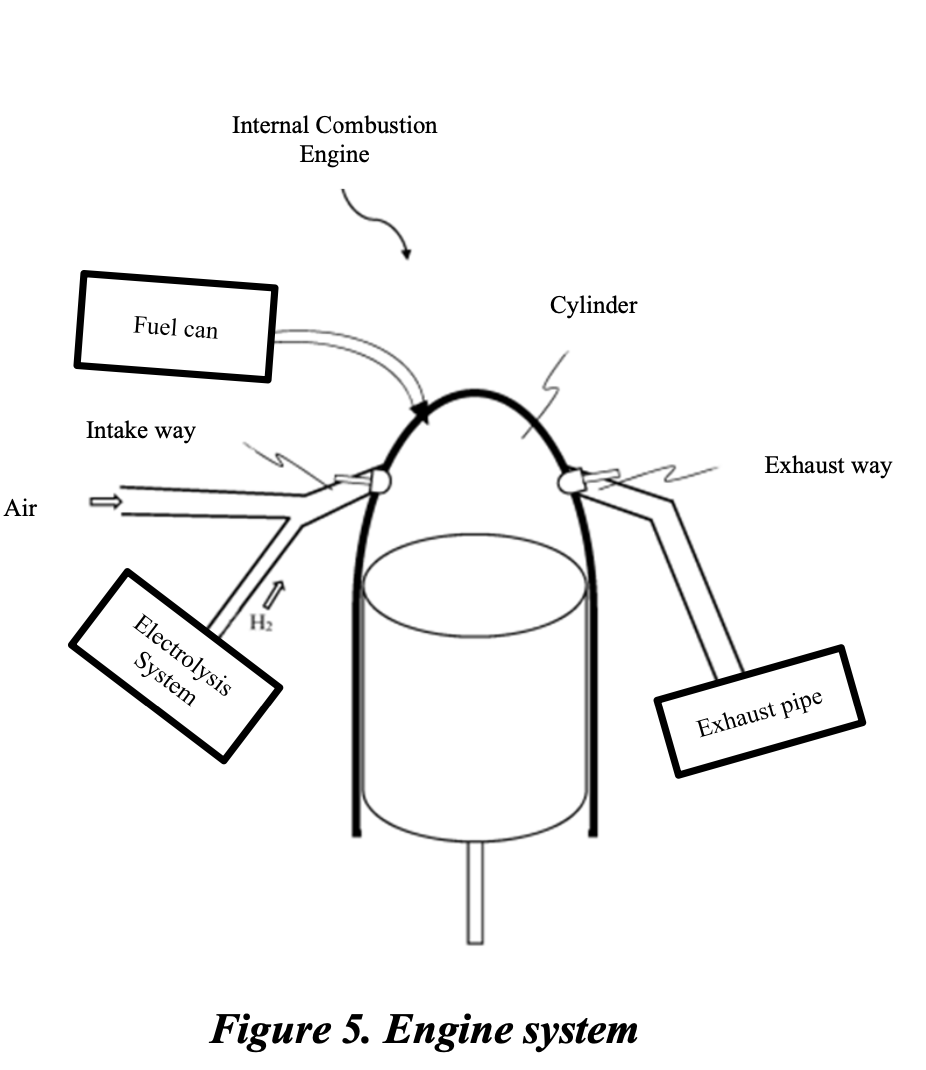

2.2.3. Engine system

Figure 5 illustrates an internal combustion engine using conventional fuel combined with hydrogen fuel. The mechanism of action is summarized as follows:

First, a combustible substance such as gasoline or diesel is introduced into the cylinder through the process of injection. Subsequently, the intake manifold facilitates the delivery of a precisely measured mixture of air and hydrogen gas (produced through the process of electrolysis) into the cylinder, in accordance with the predetermined parameters established by the operator. Subsequently, the amalgamation comprising of fuel, air, and hydrogen gas is combusted within the cylinder, resulting in the generation of mechanical energy. Subsequently, the exhaust gases proceed to traverse the exhaust pipe and are subsequently released into the surrounding environment. The sensors located within the exhaust pipe are responsible for gathering data pertaining to fuel residue and the presence of pregnant women. Subsequently, the objective is to mitigate the discharge of detrimental pollutants into the environment resulting from the functioning of internal combustion engines.

3. Conclusion

The technology developed by KOGI Group Joint offers a viable alternative for the next generation of internal combustion engines. This technology aims to gradually replace fossil fuels, thereby addressing the imperative for sustainable transformation and facilitating progress towards achieving the goal of net-zero emissions. The technology offers several advantages in addressing the sustainable needs:

-

Simple - In the context of car manufacturing, the utilization of hydrogen-based technology presents itself as an optional solution to address the challenges of cost and convenience encountered by electric vehicles and vehicles solely reliant on liquid hydrogen fuel. In conjunction with the conventional gasoline engine, this technology serves as a catalyst for a move towards environmentally friendly and sustainable practices. The integration of this technology into existing automobiles as an optional feature facilitates fuel efficiency and emission reduction in the engine.

-

Competitive price: The mentioned devices have the capability to be seamlessly incorporated into the existing vehicle system, obviating the need for a total replacement of the current components. Hence, there is potential for a substantial reduction in the cost of the car. Furthermore, the electrolysis system is supplied with a varied water source as the raw material, eliminating the necessity for the use of any catalyst. This results in a reduction of the operational expenses associated with the vehicle.

-

Saving fuel – environmentally friendly: The implementation of this technology in engines has the potential to achieve a significant reduction in gasoline or diesel fuel consumption, up to 40%, while simultaneously mitigating the emission of various harmful byproducts resulting from incomplete combustion in internal combustion engines. Subsequently, it becomes feasible to enhance the longevity of the engine by virtue of its capacity to efficiently combust fuel.

-

Safety - sustainability: Hydrogen fuel is exclusively produced and utilized in a direct manner just for the purpose of utility vehicle operations, hence mitigating the potential hazards associated with hydrogen storage, such as fire and explosion. The exclusive supply of hydrogen is limited to water, therefore obviating the need for meticulous planning of hydrogenation synthesis.

KOGI has documented and publicly disclosed several significant findings:

-

The patent was approved by the US Patent and Trademark Office in July 2023 (Patent Number: US 11,708,799 B1: Date of issue: Jul. 25, 2023)

-

Filed a patent application at the Japan Patent and Trademark Office in August 2023

-

Scientific article (preparing the manuscript for publication in a prestigious international scientific journal)

-

A number of sample products have been produced and used for cars running on different fuels (gasoline and diesel)

-

Several key technical specifications have been achieved:

PROMOTED

- Young translator conquers the ancient Greek classic Anabasis – Memoir of the Persian Expedition

- Austria news - Usama Nosshy channel covers Asean's 55th anniversary celebrations at the United Nations in Vienna

- VietnamPlus Newspaper reported about ASEAN's 55th anniversary at the United Nations in Vienna

MOST VIEWED

-

1

Nehammer : The future of the automotive industry depends on focusing on more progress and innovation

-

2

Also known as a people's diplomat

-

3

Russia president president putin's colors

-

4

Vietnamese Ambassador to Vienna Praises Cooperation with Egypt

-

5

TALKSHOW HUNG KING'S 62: THE MOSAICS OF THE KING XIII

The two Kings Philippe and Van der Bellen havedifferent backgrounds, one is of royal origin, and the other is a child of a refugee family (once of noble origin) but now, in the eyes of the European public, both of them are giving off a sense of courtesy, virtue and erudition.

WAJWith the attendance of many international figures, the 80th anniversary of the end of World War II was celebrated at the United Nations headquarters.

Journalist Usama Soliman

Comment